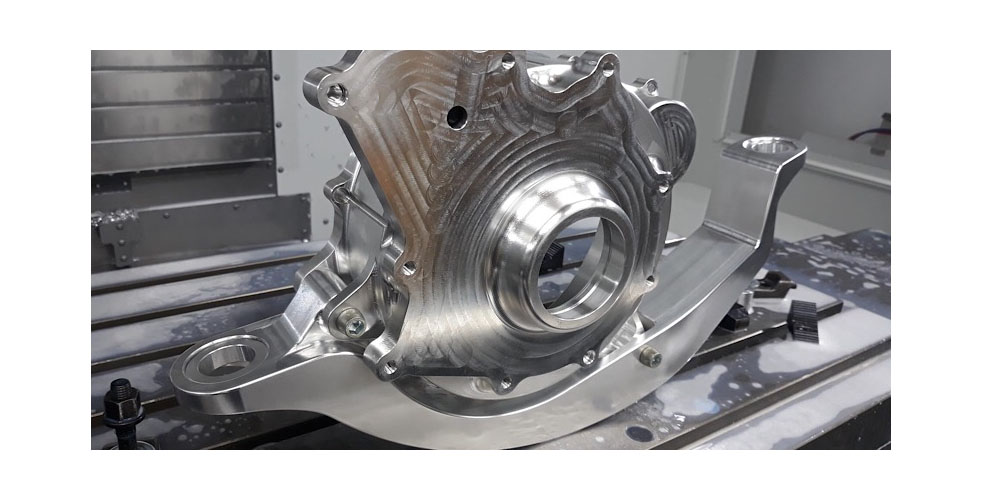

Ddprototype is one of the leading CNC machining service providers in China. The company boasts of using the best machinery and techniques for CNC metal machining. It also takes pride in applying various types of materials. for this reason, this excerpt will focus on CNC machining material qualities.

Qualities of materials used in CNC machining

Below are some qualities of CNC machining metals;

1. Corrosion resistance

One of the main qualities of materials used in CNC machining is corrosion resistance. Note that CNC machining is highly applied in industries where corrosion resistance is an important quality.

For instance, CNC machining is used to manufacture aerospace parts with complex designs and structures. Corrosion resistance translates into the durability of the parts.

For this reason, some of the most popular CNC machining materials are stainless steel and aluminum. These two materials are known for their corrosion resistance. For instance, aluminum typically features a hard coat of aluminum oxide which protects the material from reacting with environmental elements like air, which would result in rust and corrosion.

2. Good formability

Another important quality of CNC machining materials is good formability. This translates into the ease at which the material can be fashioned into various parts. This is the reason why aluminum and alloy steel are used in CNC machining. Alloy steel is especially a significant part because of its enhanced formability.

3. Weldability

Welding is a fabrication process that involves two materials being fused using heat or pressure. In CNC machining materials, weldability is an essential element. This is because the technique is used to create parts of an entire product.

For instance, in the automotive industry, the parts are manufactured independently then fused to form a whole vehicle or machine. This means that the parts have to be fused after each is manufactured. Therefore, when choosing CNC machining materials, one of the first elements to consider is weldability.

4. High strength

CNC machining materials also require to be strong. This is because the materials are subjected to harsh conditions like pressure during the machining process. Therefore, strength is a requirement because it helps prevent the materials from crumbling or getting damaged during the manufacturing process.

Additionally, the strength of the materials allows for its application in a wide range of industries. Some industries, like the aerospace and automotive industry, demand the application of highly strong materials.

5. Durability

The most commonly applied materials in CNC machining, like stainless steel, alloy steel, carbon steel alloy, and brass, are highly durable. They are resistant to issues like cracking, pitting, and corrosion.

One benefit of CNC machining is that it creates durable products. However, this benefit is mainly dependent on the materials used. For this reason, CNC machining organizations are typically very keen on the durability of the material when choosing the best fabrics.

Conclusion

The most common materials used in CNC machining are aluminum, brass, alloy steel, stainless steel, and low carbon steel. Various types of plastics are also highly applied in CNC machining. The materials used are mainly chosen based on the qualities mentioned above as well as the application. For instance, aluminum is used in automobiles and aerospace, while brass is primarily used for making electric components.