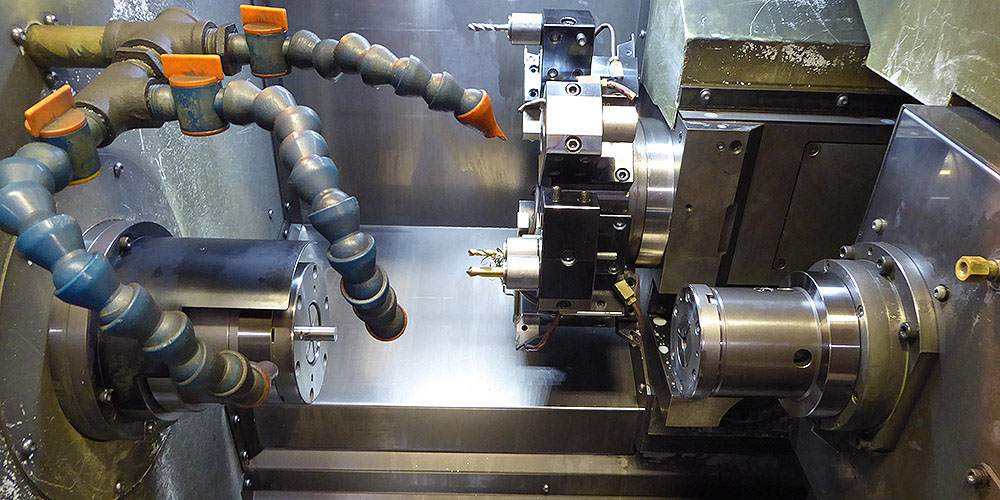

CNC turning is a subtractive manufacturing method where materials are slowly removed from a workpiece until the targeted shape is obtained. CNC turning processes manufacture metal and plastic parts with cylindrical characteristics as well as slots, grooves, flats, and radical holes. Among the CNC machining services, one of the most sought out services is the cnc turning. This article aims at informing you of the reasons to acquire CNC turning services.

Reasons to acquire CNC turning services

1. Automatic CNC turning operations

CNC turning shops have controls that allow for the automatic production of specific parts. You can program the tool movement, rotation speed, and tool selection on the CNC turning machine; therefore, reducing the need to have a technician present for the turning process.

2. High production speed

One advantage that comes with CNC turning machine is that it can work for long hours without tiring. The long working hours enables the CNC turning shops to manufacture parts quickly than the manually-run machines.

3. Precise operations

One of the best reasons to acquire CNC turning services is the assurance of precise operations and parts. It also enables parts to be created with consistency and high tolerance.

4. Low-cost

CNC turning machines have an automated system that reduces the number of working hours for the operator, therefore saving money.

5. High-levels of accuracy

CNC turning enables repeated and consistent actions, therefore ensuring high levels of accuracy. As a result of the correctness, tighter tolerances are attained.

6. Decreased levels of waste

Because of the CNC turning machine’s high level of accuracy, there is less scrap. Materials saved signify more dollars at hand.

7. High production levels

CNC turning machines have high production rates; therefore, increase the capacity of manufactured parts.

8. Highly skilled operators

The operators present to operate the CNC turning machines are highly skilled. The skilled operators follow all the manufacturing protocols effectively. Therefore, ensuring high-quality parts are produced.

9. A wide array of materials

The CNC turning services allow for the manufacture of different parts using different materials. The different materials include; plastics, copper, brass, aluminum, and stainless steel.

Types of CNC turning machines

1· Swiss-type machine

The Swiss-type turning machine is famous for full automated processes, faster cycle times, and higher production rates. The machine usually runs small parts 1.25″ and below. The Swiss-type machine is an important CNC turning machine. It slides materials across a rotating collet where several tools advance the material and perform several operations at once. The Swiss-type machine is often used in the gas, contact, and medical industry.

2· Vertical turning Lathes (VTL’s)

The VTL’s is large and is employed in large gear rings, valve housing, and several others. The VTL’s work is to cut the workpiece and perform machine operations.

Conclusion

The CNC turning machine can either be vertical or horizontal; it all depends on the workpiece’s tolerance and weight. The latest technologies in CNC allow for turning operations to occur with minimal supervision. CNC turning services is an extremely beneficial service to outsource. It is very consistent and allows for little or no human error. Its actions can be repeated several times, ensuring accuracy and exact outcomes for all parts.

In addition, the CNC turning machines are very safe as the technician does not necessarily operate the machine manually. There is a guard or protective barrier in place that protects the operator, therefore no workplace accidents.