If you are not aware of soldering machines, then here you are at the right place. Let’s introduce the machine with its basic definition. Soldering machines are used widely throughout the world to make the joining process easy.

The soldering machines have the capability to join various types of metals by melting solder. The strong pieces of metals can be joined easily together when a solder machine melts them into one piece.

Solder is an alloy of tin and lead that is melted using a hot iron. The iron is heated to a temperature above 600 degrees Fahrenheit and then cooled to form a strong electrical bond.

How Does The Machine Works?

As we discussed above that the soldering machine is used to melt metal by using heat from an iron that is connected to a temperature controller. The machine heats up so quickly to reach its melting point at 600 degrees Fahrenheit, and it allows users to start the melting process.

With a desoldering tool, solder can also be removed from electrical joints. However, solder machine is reliable in using filler metals that were once (lead solder); however, as technology develops, lead solders are now replaced with lead-free solders.

Though, the new lead-free solders may consist of brass, antimony, copper, bismuth, indium, tin or silver.

Factors To Consider Before Buying A Solder Machine;

Here we have some important factors to know completely before purchasing a soldering machine includes:

Power & temperature

It is the most important factor to check before buying a solder machine. Check the power outrage of the machine, is it working properly? Does the power break down repeatedly? Also, the temperature must be accurate enough to conveniently meltdown different metals in one round.

Type of the machine

Check the type of the machine, as there are various types available in the market in different sizes and shapes. Some automatic soldering machines have come up with additional features like locking the melting point or adjusting temperature depending on the need.

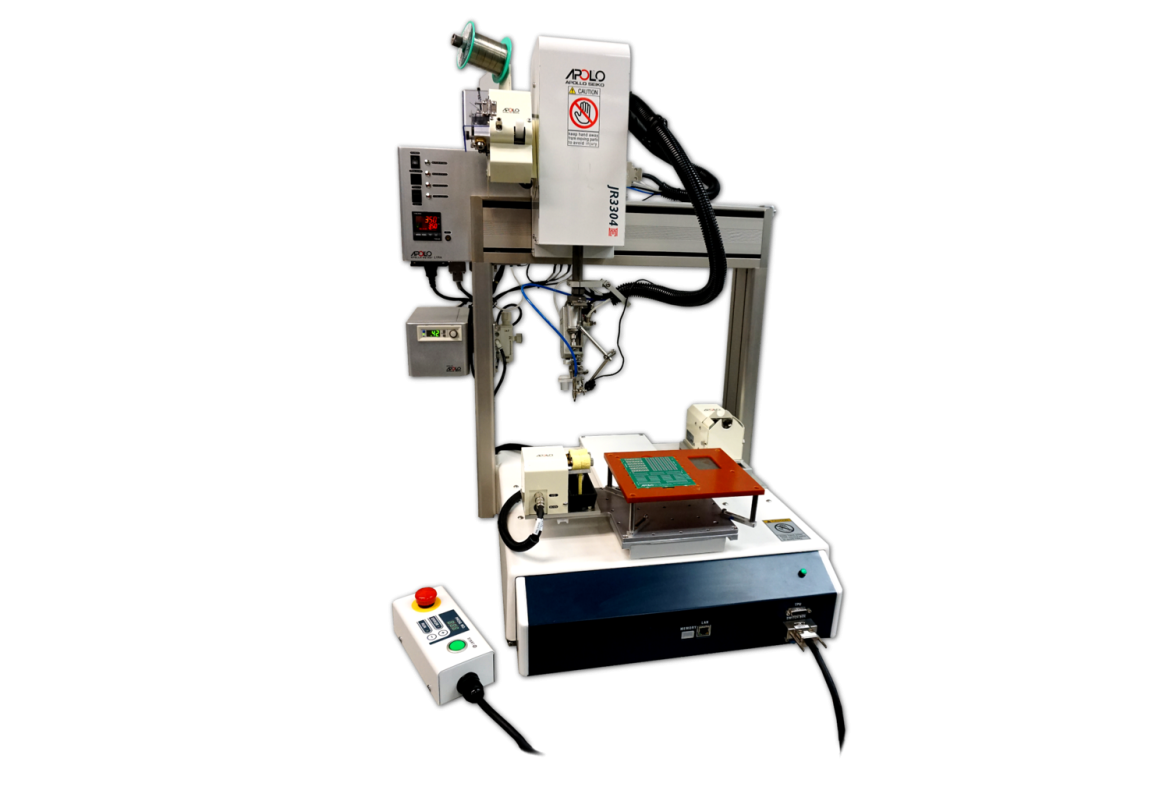

Automatic soldering machine

You can find enough space to melt efficiently when you have an automatic solder machine. Automatic solder machines are also higher in the budget, so many users don’t choose that option. Still, these automatic machines offer more accurate results if we talk about reliability and durability.

Additional built-in features

A solder machine must have additional built-in features like LED, USB option, AC/DC, and more. Sometimes we forget to check built-in features and walk off directly to the purchasing point. When an automatic solder machine has built-in features, it will give you a long lifespan.

Conclusion

There are two soldering machines available in the market; 1) automatic and 2) semi-automatic. You can choose which one full fill your needs; however, automatic machines are fully operational and have many built-in features, while semi-automatic ones sometimes take time to become functional. But as we mentioned above that always check the machine’s power and temperature control before going for any decision.