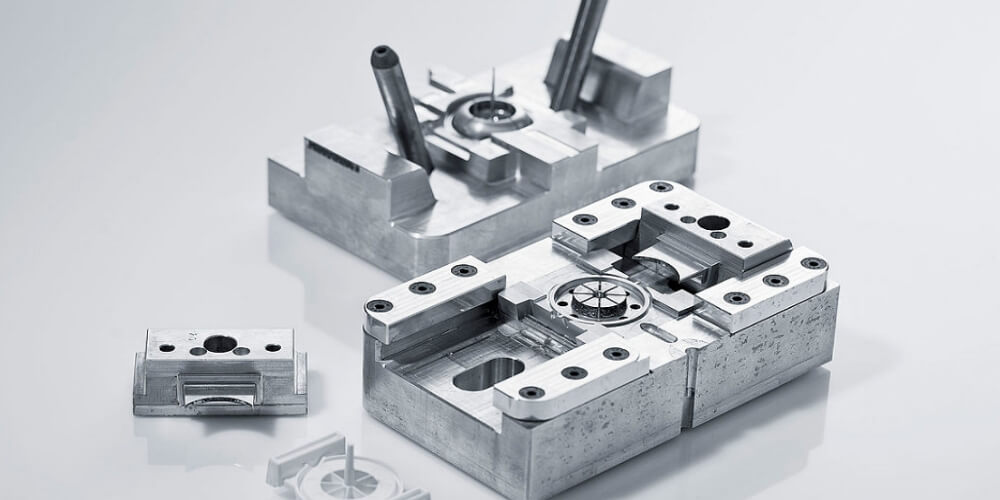

Rapid tooling is a prototyping technique used to make molds and dies quickly. This method is widely used to streamline the mold structure at a lower cost. Mold parts are made from CAD files. It is quite easier to produce CAD files. That makes rapid tooling a cost-efficient and convenient when compared to traditional manufacturing methods.

The right rapid tooling method to use is dependent on different factors such as cost, materials, and customer needs. These are some types of rapid tooling that are widely used by manufacturers.

Silicone Rubber Molds

This is another popular method of rapid tooling. As you know, silicone is an important material that is versatile and allows for molding master patterns to create a cavity. These molds are widely used in producing epoxy and urethane prototypes. This technique allows for the making of molds from thermoset materials. For instance, it is perfect for polyurethane, a material that mimics both the thermal and mechanical properties of ABS and nylon.

The good thing about silicone rubber molds is that they offer an easier method of making cheaper molds using different materials. Also, the method is suitable for both large and small parts. However, since the method uses urethane materials, their properties vary from thermoplastics that are commonly used in manufacturing.

Vacuum Casting

You can produce plastic parts by placing the silicone tool in the vacuum chamber plus a resin made of polyurethane. The mixture is de-gassed before it is poured into a cavity. As a result, an exothermic reaction occurs, and the part is removed from the cavity. You can then close the cavity and repeat the process.

Cast Resin Tooling

The rapid tooling technique is regarded to be the simplest method of making an injection molding tool. Ideally, you need to mount a pattern with a mold box and set up the parting line. Once you complete the process, you can repeat it as much as you want. You can use different tooling resins that are readily available. One of the resins is commonly used is epoxy. The good thing about this method is that it is simple and fast. However, it is only suitable for parts with simple shapes.

Spray Metal Tooling

The rapid tooling method is suitable for production. In this case, you need to spray a shell of 2 mm over a pattern with epoxy resin to add rigidity. The metal tools produced can make thousands of parts as long as they are well-maintained. This technique is used in different processes, such as sheet metal forming, compression molding, and injection molding. You will find this method to be faster. Unfortunately, you cannot use it to spray deep holds and narrow slots. Thus, you have to ensure the parts you produce have simple geometry.

Electroforming

This method uses the electroplating technique to create a mold. Thus, you have to make the surface of the metal to be electrically conductive. The best option is to add a layer of conductive lacquer. This is a perfect method for making tools for shoe soles that have complex patterns. Nickel is regarded to be suitable for electroforming as it has excellent strength and thermal conductivity.