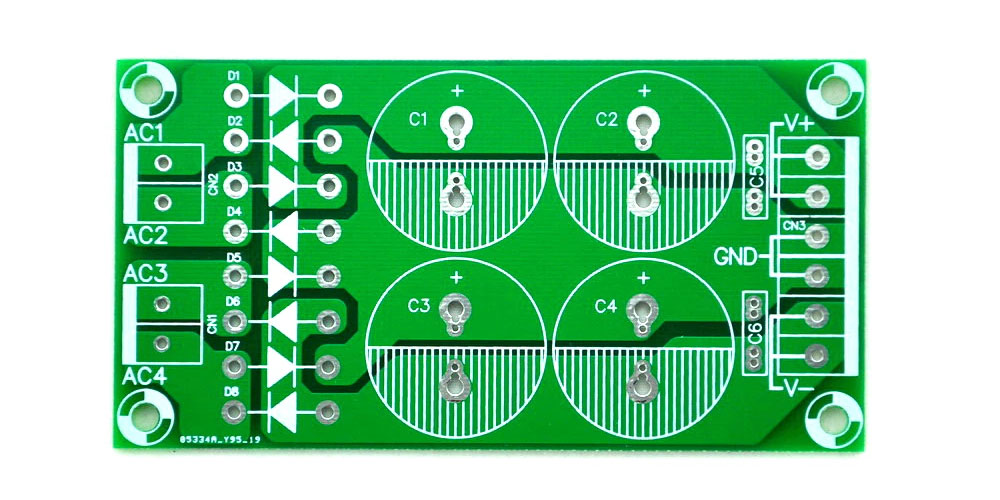

PCB is crucial in the power industry. Furthermore, the power industry cannot function properly without the use of PCB. Power supply PCB is found in most systems at homes, such as TV, computers, radio, and home appliances. Additionally, power PCB ensures that Ac power is concerted to DC while ensuring minimal noise is applied. It also limits the maximum voltage, therefore, prevents damage to electronics from too much voltage. Furthermore, power supply PCB has several features that ensure the smooth running of the PCB; some of those features include;

Some attributes of power supply PCB

1. High output stability

Power supply PCB has a high-speed response rate system. The high-speed response rate system ensures that the circuit board is highly adaptable to load and network power changes. Furthermore, a power supply PCB has an output accuracy level that is higher than 1%. Also, it has high switching power supply efficiency that ensures high control accuracy. High control accuracy provides room for increased product quality.

2. Lightweight and small in size

Most power supply PCB has a volume of 1/5 to 1/10. The power supply’s small size and weight PCB ensure that the power supply is easy to move, install, maintain, plan, and expand. Therefore, the convenience offered by the small size ensures that the power PCB saves on the material during the production process.

3. Easy to regulate output waveform

Power supply PCB allows for the convenient modulation of the output waveform. The suitable regulation is due to the high-frequency operations. Furthermore, the output waveform processing cost is pretty low, thus ensuring that the output waveform can easily be changed according to one’s needs. The easy regulation of output waveform provides the quality of manufactured products and efficiency in workplaces.

4. Energy saving

The power supply PCB energy-saving trait can be attributed to its adoption of the high-frequency transformer. The high-frequency transformer also encourages the improvement of conversion efficiency.

5. Reliable

Power supply PCB’s use of the new monitoring circuit and power supply operations ensures that it is very reliable in all its processes. Furthermore, the new procedures also provide that the power supply saves on raw material, reduces work time, and reduces costs.

6. High quality

The power supply PCB is made of quality materials such as nanocrystalline. The quality materials used ensure that the overall PCB is quality. Furthermore, the excellent structure also contributes to its high quality.

Factors to consider in power supply PCB design process

- Selecting the correct regulator: Generally, there are two regulators, switched-mode and linear regulators. The linear regulators ensure that the noise output is low but requires cooling systems because of high heat dissipation. While the switched-mode regulators are very efficient but sometimes may have high noise output.

- Thermal management: It is crucial to consider thermal management while designing for a power PCB as its performance relies heavily on its power dissipation ability.

- Power and Ground planes: Power and ground planes are crucial in ensuring a good PCB power supply. Therefore, it should be among critical considerations while designing power PCB.

Conclusion

Accurate electronic device functioning depends heavily on excellent power supplies. Therefore, considerations should be taken place in the designing and production process of power supply PCB. Also, the various attributes of a power supply PCB aim to ensure efficiency, reliability, and quality.